Superalloy InconelX-750 / UNS N07750 / AlloyX-750 Seamless Yeeb Nkab, Ntawv, Hlau

Cov khoom muaj

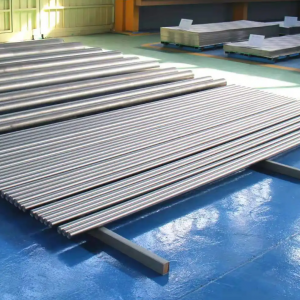

Seamless raj, phaj, pas nrig, forgings, fasteners, yeeb nkab fittings

Cov qauv tsim

| Khoom | ASTM |

| Bars thiab Forgings | ib 637 |

Tshuaj muaj pes tsawg leeg

| % | Ni | Cr | Fe | C | Mn | Si | S | Ti | Nb+Ta | Al | Co | Cu |

| Min | 70.0 ua

| 14.0 Nws | 5.0 |

|

|

|

| 2.25 | 0.70 ib | 0.40 Nws |

|

|

| Max | 17.0 Nws | 9.0 ib | 0.08 ib | 1.00 Nws | 0.50 ib | 0.010 ib | 2.75 ib | 1.20 | 1.00 Nws | 1.00 Nws | 0.50 ib |

Lub cev muaj zog

| Qhov ntom | 8.28 g / cm3 |

| Melting | 1393-1427 ℃ |

Inconel X-750 nta

Inconel X-750 alloy feem ntau yog npib tsib xee-based superalloy uas muaj hnub nyoog muaj zog nrog γ [Ni3 (Al, Ti, Nb)] theem.Nws muaj kev tiv thaiv corrosion zoo thiab oxidation tsis kam qis dua 980 ℃, thiab qis dua 800 ℃ Nws muaj kev tiv thaiv corrosion siab.Nws muaj qhov zoo so tsis kam qis dua 540 ° C, nrog rau kev tsim tau zoo thiab weldability.Cov hlau no tsuas yog siv rau kev tsim cov tshuab dav hlau uas ua haujlwm qis dua 800 ° C thiab xav tau lub zog siab..Springs kuj tseem siv tau los tsim cov tshuab hluav taws xob turbine thiab lwm yam, xws li daim hlau, strips, tuav, forgings, rings, xov hlau, kav dej, thiab lwm yam.

Inconel X-750 Cov txheej txheem kho cua sov

Kev daws teeb meem kev kho cua sov rau daim hlau, strips thiab cov kav dej hauv lub xeev muab khoom yog 980 ℃ ± 15 ℃, cua txias.Rau kev kho cua sov nruab nrab ntawm cov khoom siv thiab cov khoom, cov txheej txheem hauv qab no tuaj yeem raug xaiv rau kev kho cua sov.

Annealing: 955 ~ 1010 ℃, dej txias.

Annealing ntawm welded qhov chaw ua ntej welding: 980 ℃, 1h.

Kev ntxhov siab nyem annealing ntawm welded qhov chaw: 900 ℃, moisturizing rau 2h.

Kev ntxhov siab rau annealing: 885 ℃ ± 15 ℃, 24h, cua txias.

Inconel X-750 Muaj ntau yam thiab Specifications

Bars, forgings, rings, cov ntawv kub dov, cov ntawv txias-dov, strips, raj thiab xaim tuaj yeem muab tau rau ntau qhov ntau thiab tsawg.

Daim hlau thiab strips feem ntau yog muab tom qab kub los yog txias dov, annealing los yog tov, pickling thiab polishing.

Bars, forgings thiab rings tuaj yeem muab rau hauv lub xeev forged lossis kub dov;lawv kuj tuaj yeem muab nkag rau hauv kev kho mob tom qab forging;tuav tuaj yeem muab tom qab kev daws teeb meem thiab polished los yog tig, thiab tuaj yeem muab tau rau hauv txias thaum qhov kev txiav txim yuav tsum rub lub xeev rau hauv qhov chaw.

Cov xaim tuaj yeem muab nkag rau hauv lub xeev cov tshuaj tov khoom;rau cov hlau nrog lub nominal txoj kab uas hla los yog thickness hauv qab no 6.35mm, nws yuav ua tau cov khoom tov thiab muab nrog ib tug txias kos deformation ntawm 50% mus rau 65%;lub nominal txoj kab uas hla los yog sab ntev yog ntau tshaj 6.35mm.Hlau, tom qab kev daws teeb meem, yog muab los ntawm kev kos duab txias deformation tsis pub tsawg dua 30%.Rau cov xov hlau uas muaj lub taub nominal lossis sab ntev tsis ntau dua 0.65mm, lawv tuaj yeem muab cov duab txias deformation tsis pub tsawg dua 15% tom qab kev daws teeb meem raws li qhov xav tau.

Inconel X-750 Daim Ntawv Thov Cheeb Tsam

Cov hlau yog tsuas yog siv rau kev tsim cov nplooj springs thiab coil springs nrog siab zog yuav tsum tau thiab so tsis kam rau aero-engines khiav hauj lwm hauv qab no 800 ° C.Nws kuj tseem siv tau los ua cov khoom xws li turbine hniav.Muaj ntau yam yog daim ntawv, sawb, bar, forging, nplhaib, hlau thiab raj.