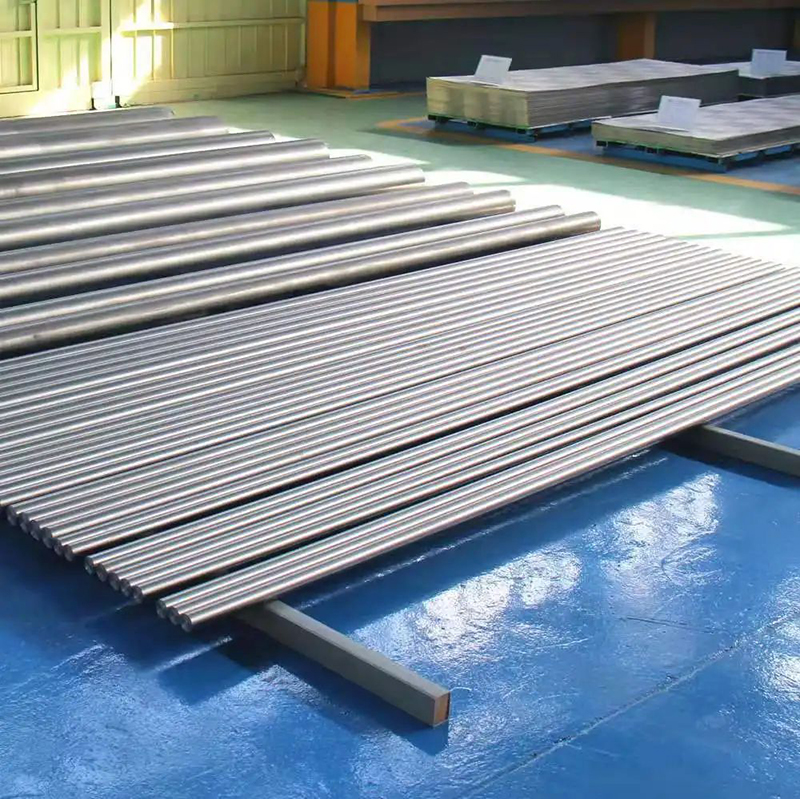

Chaw tsim tshuaj paus kev HastelloyC22 / UNS N06022 Tube, Phaj, Qws

Cov khoom muaj

Seamless Tube, Phaj, Qws, Forgings, Fasteners, Sawb, Hlau, Yeeb Nkab Fittings

Tshuaj muaj pes tsawg leeg

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S | |

| C22 | min | tshuav nyiaj li cas | 20.0 Nws | 12.5 ib | 2 | 2.5 | |||||||

| max | 22.5 ib | 14.5 ib | 6 | 3.5 | 2.5 | 0.015 ib | 0.5 | 0.08 ib | 0.35 Nws | 0.02 ib | 0.02 ib |

Lub cev muaj zog

| ceev | 8,9g 3 |

| Melting | 1325-1370 ℃ |

Yam tsawg kawg nkaus txhua yam khoom ntawm Hastelloy C-22 alloy ntawm chav tsev kub

| Alloy | Rm N/mm2 | RP0.2N / hli 2 | A5% |

| Hastelloy C22 | 690 ib | 283 | 40 |

Alloy khoom

Hastelloy C22 alloy muaj kev tiv thaiv zoo rau pitting corrosion, crevice corrosion thiab kev nyuaj siab corrosion cracking.Nws muaj kev tiv thaiv zoo heev rau oxidative aqueous media nrog rau cov chlorine ntub dej, nitric acid los yog sib tov ntawm oxidative acids uas muaj chloride ions.Nyob rau tib lub sijhawm, Hastelloy C22 alloy kuj muaj qhov zoo tshaj plaws tiv thaiv kom txo tau thiab oxidizing ib puag ncig ntsib hauv cov txheej txheem.Kev cia siab rau qhov kev ua tau zoo no, nws tuaj yeem siv rau qee qhov teeb meem ib puag ncig, lossis hauv ntau lub hom phiaj tsim khoom.Hastelloy C22 alloy muaj qhov tshwj xeeb tiv thaiv rau ntau yam tshuaj ib puag ncig, suav nrog cov khoom muaj zog oxidizing xws li ferric chloride, cupric chloride, chlorine, thermally polluted daws (organic thiab inorganic), formic acid, acetic acid, acetic anhydride, seawater thiab ntsev tov, thiab lwm yam. Hastelloy C22 alloy muaj peev xwm tiv thaiv kev tsim cov qoob loo ciam teb nag lossis daus hauv qhov vuam kub cuam tshuam cheeb tsam, uas ua rau nws tsim nyog rau ntau cov txheej txheem tshuaj siv nyob rau hauv lub xeev welded.

Metallographic qauv

Hastelloy C22 muaj lub ntsej muag-centered cubic lattice qauv.

Corrosion kuj

Hastelloy C22 alloy yog haum rau ntau yam kev lag luam chemical industries uas muaj oxidizing thiab txo cov xov xwm.Qhov siab dua molybdenum thiab chromium cov ntsiab lus ua rau cov alloy resistant rau chloride ions, thiab cov khoom tungsten ntxiv txhim kho nws cov corrosion kuj.Hastelloy C22 yog ib qho ntawm ob peb cov ntaub ntawv tiv thaiv corrosion hauv cov tshuaj chlorine ntub dej, hypochlorite, thiab chlorine dioxide daws.tooj liab chloride).

Daim ntawv thov teb

Hastelloy C22 alloy yog dav siv nyob rau hauv tshuaj thiab petrochemical teb, xws li Cheebtsam thiab catalytic systems nyob rau hauv kev sib cuag nrog chloride-muaj organics.Cov khoom no yog tshwj xeeb tshaj yog haum rau siv nyob rau hauv high kub, inorganic thiab organic acids tov nrog impurities (xws li formic acid thiab acetic acid), thiab seawater corrosive ib puag ncig.

Lwm qhov chaw thov

1. Acetic acid/acetic anhydride

2. Pickling

3. Cellophane manufacturing

4. Chlorination system

5. Complexed Acids

6. Rollers ntawm electro-galvanizing tank

7. Expansion bellows

8. Flue gas tu system

9. Geothermal Wells

10. Hydrogen fluoride rauv tshuab ntxhua khaub ncaws

11. Incineration cleaner system

12. Nuclear roj rov tsim dua tshiab

13. Cov tshuaj tua kab ntau lawm

14. Phosphoric acid ntau lawm

15. Pickling system

16. Phaj kub exchanger

17. Xaiv qhov system lim

18. Sulfur dioxide txias ntauwd

19. Sulfonation system

20. Tube kub exchanger

21. Surfacing valve