Chaw tsim tshuaj paus HastelloyC4/UNS N06455 Tube, Phaj, Qws

Cov khoom muaj

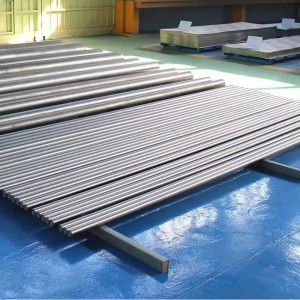

Seamless Tube, Phaj, Qws, Forgings, Fasteners, Sawb, Hlau, Yeeb Nkab Fittings

Tshuaj muaj pes tsawg leeg

| % | Ni | Cr | Mo | Fe | Ti | Co | C | Mn | Si | P | S | V |

| Min | Tshuav | 14.0 Nws | 14.0 Nws | |||||||||

| Max | 18.0 Nws | 17.0 Nws | 3.0 | 0.7 ua | 2.0 | 0.015 ib | 0.50 ib | 0.08 ib | 0.040 ib | 0.030 Nws | 0.35 Nws |

Lub cev muaj zog

| Qhov ntom | 8,64g 3 |

| Melting | 1350-1400 ℃ |

Hastelloy C-4 yog austenitic tsawg carbon nickel-molybdenum-chromium alloy.Qhov sib txawv tseem ceeb ntawm Hastelloy C-4 thiab lwm yam ua ntej tsim alloys ntawm cov tshuaj zoo sib xws yog cov pa roj carbon tsawg, silicon, hlau, thiab cov ntsiab lus tungsten.Xws li cov tshuaj muaj pes tsawg leeg ua rau nws muaj kev ruaj ntseg zoo ntawm 650-1040 ° C, txhim kho kev tiv thaiv intergranular corrosion, thiab tuaj yeem zam cov ntug-kab corrosion tsis kam thiab weld tshav kub-cuam tshuam cheeb tsam corrosion raws li tsim nyog tsim.

Khoom Khoom

● Zoo heev corrosion kuj rau feem ntau corrosive media, tshwj xeeb tshaj yog nyob rau hauv lub xeev txo.

●Zoo heev localized corrosion kuj ntawm halides.

Daim ntawv thov teb

Nws tau siv dav hauv ntau thaj chaw tshuaj thiab qhov chaw kub kub.Tej thaj chaw thov:

●Flue gas desulfurization system

● Pickling thiab acid regeneration cog

●Acetic acid thiab agrochemical ntau lawm

●Titanium dioxide ntau lawm (chlorine method)

●Electrolytic plating

Vuam Performance

Hastelloy C-4 tuaj yeem welded los ntawm ntau yam txheej txheem vuam, xws li tungsten electrode inert gas shielded vuam, plasma arc vuam, phau ntawv sub-arc vuam, hlau shielded inert gas welding, thiab molten inert gas shielded vuam.Pulse arc vuam yog nyiam.

Ua ntej vuam, cov khoom yuav tsum nyob rau hauv lub xeev annealed kom tshem tawm oxide nplai, roj stains thiab ntau yam cim, thiab qhov dav ntawm li 25 hli ntawm ob sab ntawm lub vuam yuav tsum polished rau ib tug kaj hlau nto.

Nrog rau cov cua kub tsis tshua muaj, qhov kub ntawm interlayer tsis tshaj 150 ° C.