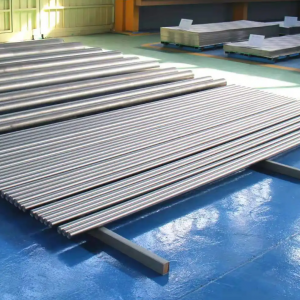

Inconel718 / UNS N07718 Yeeb Nkab, Phaj, Bar Professional Chaw tsim tshuaj paus

Cov khoom muaj

Seamless raj, phaj, pas nrig, forgings, fasteners, yeeb nkab fittings

Cov qauv tsim

| Khoom | ASTM |

| Bars thiab Forgings | ib 637 |

| Phaj, Sheet thiab Sawb | ib 670b906 |

| Seamless kav thiab fittings | ib 983 |

Tshuaj muaj pes tsawg leeg

| % | Ni | Fe | Cr | Mo | C | Mn | Si | P | S | Co | Nb+Ta | Ti | Al | Cu | B |

| Min | 50.0 ua |

| 17.0 Nws | 2.80 Nws |

|

|

|

|

|

| 4.75 ib | 0.65 ib | 0.20 ib |

|

|

| Max | 55.0 ua | 21.0 Nws | 3.30 Nws | 0.08 ib | 0.35 Nws | 0.35 Nws | 0.015 ib | 0.015 ib | 1.00 Nws | 5.50 Nws | 1.15 | 0.80 ib | 0.30 Nws | 0.006 ib |

Lub cev muaj zog

| ceev | 8.23g / cm3 |

| Melting | 1260-1335 ℃ |

Inconel 718 nta

Inconel 718 yog nag lossis daus hardening npib tsib xee-raws li superalloy nrog kub kub corrosion kuj zoo heev.Feem ntau siv nyob rau hauv kev lag luam aerospace, Inconel 718 muaj siab kub txhua yam lub zog thiab zoo heev ductility mus txog 704 ° C / 1300F.Nws yog non-magnetic nyob rau hauv cov xwm.

Nickel-based superalloy 718 muaj kev tiv thaiv zoo rau oxidation thiab lwm yam corrosion nyob rau hauv qhov chaw dav hlau cav thiab av-raws li roj turbine daim ntaub ntawv.Nws yog cov khoom siv zoo tshaj plaws rau cov ntawv thov uas xav tau kev tiv thaiv zoo heev rau kev nkag thiab kev ntxhov siab corrosion tawg (txog 982 ° C lossis 1800F).Alloy 718 muab kev tiv thaiv tag nrho ntawm pitting thiab crevice corrosion hauv sulfides, chlorides, carbon dioxide thiab lwm qhov chaw hnyav.

Inconel 718 muaj cov khoom zoo hauv qhov kub ntawm -253 txog 700 ° C, lub zog tawm los qis dua 650 ° C yog thawj zaug hauv deformed superalloys, thiab muaj kev qaug zog zoo, tiv thaiv hluav taws xob, tiv thaiv oxidation, corrosion resistance, thiab kev ua haujlwm zoo.Kev ua tau zoo, vuam kev ua tau zoo thiab lub sijhawm ntev kev ruaj ntseg, nws tuaj yeem tsim ntau qhov chaw nrog cov duab nyuaj, thiab tau siv dav hauv qhov ntsuas kub saum toj no hauv aerospace, nuclear zog, thiab roj av industries.

Inconel 718 alloy yog nag lossis daus hardening nickel-chromium-hlau alloy uas muaj niobium thiab molybdenum.Nws muaj lub zog siab, zoo toughness thiab corrosion kuj nyob rau hauv siab thiab qis kub ib puag ncig hauv qab 650 ℃.Lub xeev no yuav raug kho los yog nag lossis daus hardened.

1. Yooj yim rau txheej txheem

2. Siab tensile zog, qaug zog zog, creep zog thiab rupture zog ntawm 700 ℃

3. 1000 ℃ siab oxidation kuj

4. Chemically ruaj khov ntawm qhov kub thiab txias

5. Kev ua haujlwm vuam zoo

Inconel 718 Cov Qib Zoo sib xws

GH4169, GH169 (Tuam Tshoj), NC19FeNb (Fabkis), NiCr19Fe19Nb5, Mo3 (Lub Tebchaws Yelemees), NA 51 (UK) Inconel718, UNS NO7718 (USA) NiCr19Nb5Mo3 (ISO)

Inconel718 Cov Khoom Siv Khoom Siv

Vim nws lub zog kub kub ntawm 700 ° C, zoo heev corrosion kuj thiab yooj yim processability, nws tuaj yeem siv dav hauv ntau lub sijhawm xav tau.

1. Chav turbine

2.Liquid roj foob pob ua ntxaij

3.Cryogenic engineering

4.Acid ib puag ncig

5. Nuclear Engineering