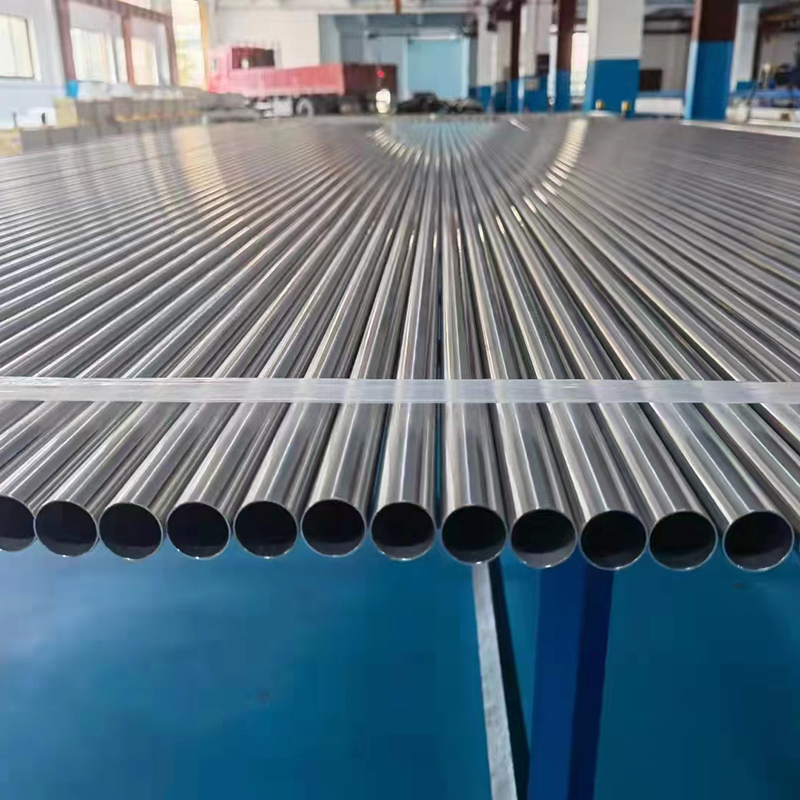

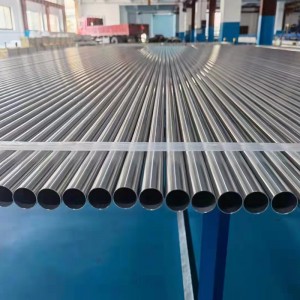

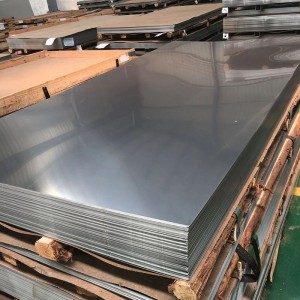

Alloy 825 / UNS N08825 / Incoloy 825 Tube Phaj Qws

Cov khoom muaj

Seamless raj, phaj, pas nrig, forgings, fasteners, yeeb nkab fittings.

Cov qauv tsim

| Khoom | ASTM |

| Bar thiab hlau | ib 425 |

| Phaj, Sheet thiab Sawb | ib 424b906 |

| Seamless kav thiab fittings | ib 423b829 |

| Welded yeeb nkab | Ib 705, B 775 |

| Weld tub | ib 704b751 |

| Welded yeeb nkab fittings | ib 366 |

| Forging | ib 564 |

Tshuaj muaj pes tsawg leeg

| % | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

| Min | 38.0 Nws | 22.0 Nws | 19.5 Nws |

|

|

|

| 2.5 | 1.5 | 0.60 ib |

|

| Max | 46.0 ib |

| 23.5 Nws | 0.05 Nws | 1.00 Nws | 0.50 ib | 0.030 Nws | 3.5 | 3.0 | 1.20 | 0.20 ib |

Lub cev muaj zog

| Qhov ntom | 8.14 g / cm3 |

| Melting | 1370-1400 ℃ |

Incoloy 825 Khoom Khoom

Incoloy 825 yog titanium-stabilized tag nrho austenitic nickel-hlau-chromium alloy nrog ntxiv ntawm tooj liab thiab molybdenum.Incoloy 825 yog lub hom phiaj dav dav engineering alloy uas tiv taus cov kua qaub thiab alkali hlau corrosion nyob rau hauv ob qho tib si oxidizing thiab txo qhov chaw.

Cov ntsiab lus siab nickel ua rau cov alloy zoo tiv thaiv kev ntxhov siab corrosion cracking.Nws muaj kev tiv thaiv corrosion zoo hauv ntau yam xov xwm, xws li sulfuric acid, phosphoric acid, nitric acid thiab organic acids, thiab alkali hlau xws li sodium hydroxide, potassium hydroxide thiab hydrochloric acid daws.Qhov kev ua tau zoo dua ntawm Incoloy 825 tau tshwm sim hauv cov khoom siv hluav taws xob sib txuas nrog ntau yam kev tawm tsam corrosive, xws li sulfuric acid, nitric acid thiab sodium hydroxide, uas yog tag nrho cov txheej txheem hauv tib yam khoom.

1.Zoo tsis kam rau kev ntxhov siab corrosion cracking

2.Zoo tsis kam rau pitting thiab crevice corrosion

3.Zoo anti-oxidative thiab non-oxidative thermal acid zog

4.Cov khoom siv kho tshuab zoo ntawm chav tsev kub thiab kub siab txog 550 ℃

5. Pom zoo rau cov hlab ntsha siab nrog kev tsim khoom kub txog 450 ℃

Incoloy 825 Material Application Areas

Incoloy 825 yog dav siv nyob rau hauv ntau yam kev lag luam teb uas qhov kev khiav hauj lwm kub tsis tshaj 550 ℃.

Tej kev siv yog:

1.Heating kav, ntim, pob tawb thiab chains siv nyob rau hauv sulfuric acid pickling nroj tsuag.

2.Seawater cooling heat exchanger, marine khoom piping system, acid gas ib puag ncig piping.

3.Heat exchangers, evaporators, scrubbers, dip raj, thiab lwm yam nyob rau hauv phosphoric acid ntau lawm.

4.Air tshav kub exchanger nyob rau hauv roj refining

5. Khoom noj khoom haus engineering

6. Cov txheej txheem tshuaj

7.Flame retardant alloy rau siab siab oxygen daim ntaub ntawv